BOA Technologies feels the days for boots buckles are numbered and they have the data to back it in the linked study: Evaluating wrapping alpine ski boots during on-snow carving. Recently we were invited to the BOA Technology headquarters in Denver, Colorado to tour their extensive facilities, discuss BOA on ski boots and its future in the ski industry.

"Atomic was fortunate to be a key partner in the development of the new H+i1 system back in 2018 and we’re incredibly excited with what the future has in store. We’ve always been obsessed with creating better fitting, better skiing boots and this solution we’ve worked on with BOA is doing just that."--Matt Manser, Global Product Manager of Alpine & Touring Boots

Not just a gimmick

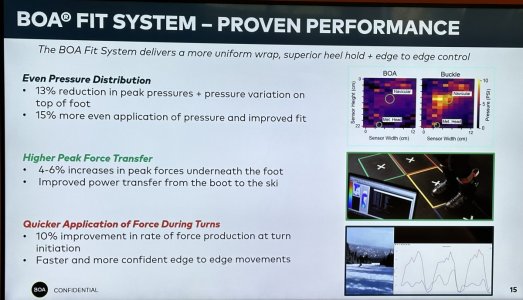

BOA is not just an alternative closure system to replace traditional buckles. BOA Technologies offers an enhancement system that is designed to increase performance. BOA does not enter a market or segment without a clear goal of making that product perform better. Think of the old BASF commercial’s slogan: BASF: We don’t make the products you buy, we make the products you buy better”. That’s BOA, they don’t make the ski boots we ski in, they make the boots we ski in better.”

"BOA offers a new way to think about boot construction and we believe we can build a boot which offers both more comfort and performance than buckles. Building boots which offer the best experience to as many skiers as possible is our goal and we believe BOA helps K2 build the best boots possible".—Tom Pietrowski, Global Product Line Manager for K2 ski boots

BOA Technologies has over 280 patents with 95 of them obtained in the past year. The first number they threw out to us was that 75% of the Tour De France riders were using shoes that were BOA-integrated. So while we can talk about cycling, golf, work boots, snowboard boots, medical braces, and all of the other applications that have BOA, we are here to talk ski boots.

BOA produces over 40 million closures a year. They do not just send them to brands and ask to put them on their products and hope that they will become a partner. BOA’s facility in Denver is not just a marketing center or global headquarters, it is a complete research and development facility with the ability to reverse engineer any and every product they feel BOA can enhance. They have test in controlled environments and in the real world with their in-house team of over 300, plus another 4-500 field testers of elite athletes.

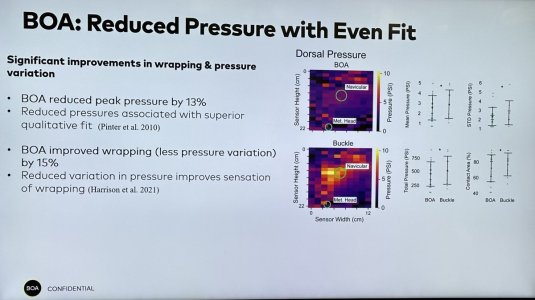

I will start by saying I like my crow with a light demi-glace when I eat it, because I too was one of the uninformed thinking BOA was just a basic alternative to buckles on a boot. I could not be more wrong. While BOA will close the clog (lower shell) of the boot, it is how BOA encompasses and uniformly holds and contains the foot that improves performance, and those findings were clear in their recent study whiich is linked above.

Creating a ski boot mold is not an inexpensive process. Each mold in each size is incredibly expensive to produce, over $100,000 per shell. Considering that there are size runs of boots, these can add up quickly to above one million dollars, and that is for each model of boot! Manufacturers don’t make that level of financial commitment unless there is a measurable difference in performance and not just a lateral move for the same performance return.

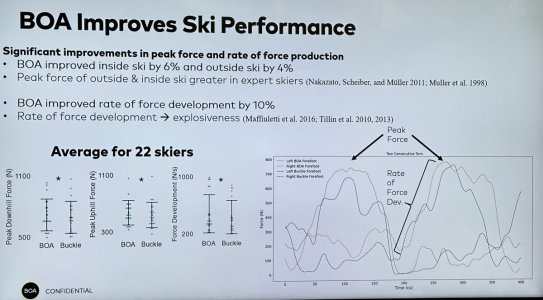

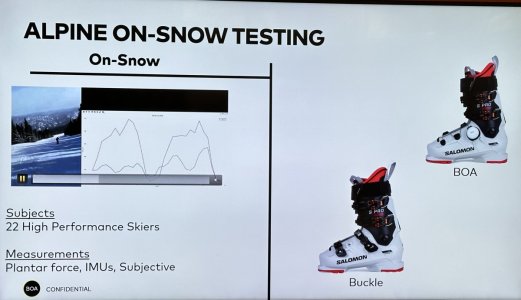

The ski boot manufacturers did not go to BOA, BOA did years of research, bought defunct molds of boots, built said boots with buckles and with BOAs to secure their findings. They went to the brand which whom they had an established relationship with a clear vision and said, “We can make your boots better and we have the proof." This was enough for each of these brands to sit up and listen. As a result, we are now seeing BOA on 24 different model boots from four brands for the 23/24 ski season.

BOA conducted their own on-snow test of their system with 22 skiers at Eldora Mountain. Their numbers show more than 10% improvement in performance. Where even a 5% increase in performance would be significant, a 10% increase is something any high level athlete would sell their first born for. This test proved that performance does not have to come at the cost of comfort.

If BOA was just an easy fit solution, we would have seen it starting on entry level boots as well as the rental market, but BOA is indeed a performance enhancement. Hence, they put a bullseye on the most contested segment of boots, the mid volume 100-ish to 130-ish flex boots as well as side country boots. Will we see narrow last boots with BOA? Absolutely. Performance is first and foremost. I would not be surprised if in a few years we see brands exclusively with BOA closures.

To the naysayers who say, “I will believe it when I see BOA on a race boot,” race boots are coming. We might not see them in the 2024 season, but pretty soon thereafter. Testing is occurring and from what we are told, the results are all that BOA hoped for and more. It is enough to expect that 30% of racers at the next Olympics will be in BOA boots, a lofty claim? Maybe, but nothing I have heard from them has been off too much, so until then I have to believe them.

BOA on the upper cuff? Yes, that is in the works too; we will see dual BOA boots coming soon. For this year, four brands of boots have adopted BOA: Atomic, Fischer, K2 and Salomon. For 2024 we will see more brands integrating it. This truly is an exciting time in the boot market and BOA is the word of the year.

You can read additional BOA discussions here..Comparing the 2024 Boa Boots Offerings from Atomic, Fischer, K2 and Salomon

Study: Evaluating wrapping alpine ski boots during on-snow carving

While BOA did not cover air fare, they did cover local transportation and food along with supplying a nice goody bag, and will be providing a pair of BOA boots for our test fleet.