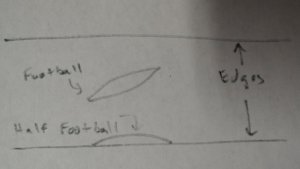

I did a experiment with JB weld before fixing mine shot. I mixed a small amount put in 2 piles, I then put ptex right over before it cured. Came back in 20 to check adhesion and man that ptex stuck so I went ahead and did my ski. The second pile I was going to wait till JB cured and then ptex,but with results I got before cured I was very happy with I didn’t bother. View attachment 87773 View attachment 87774 View attachment 87775

Photo of final scraping? Or you just going to ski it like that?