Hi All,

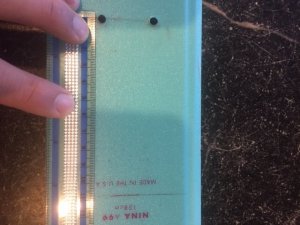

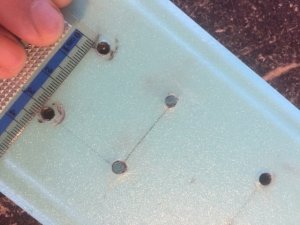

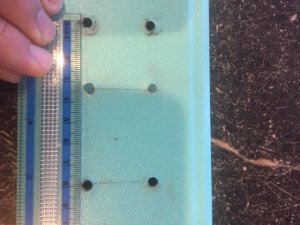

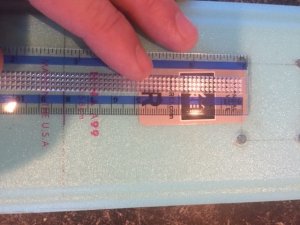

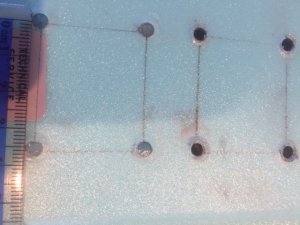

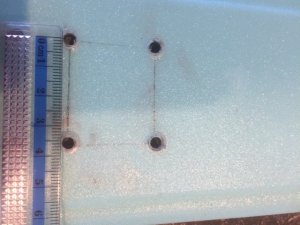

I just picked these skis up for my wife locally at a REI garage sale. They've been drilled twice, and while I was a little nervous about a potential conflict, I went for it.

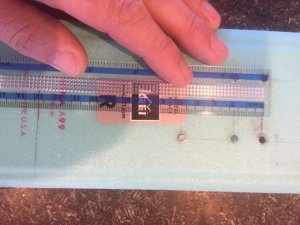

I was hoping to mount the Tyrolia Attack 13 demo's on it, which I've seen on closeout. I downloaded a paper template and held it up to the ski, and it seemed fine, but it's not exactly precise.

Can any folks with lots of binding experience chime in? Anyone recognize the hole pattern?

The Tyrolias have 95 mm brake, and this waist is 99, but in the FAQ of the site, they mentioned being able to mount the 95 mm brake on 104 mm waist.

If Tyrolias won't work, can I move to another brand with different hole pattern?

Thanks!

I just picked these skis up for my wife locally at a REI garage sale. They've been drilled twice, and while I was a little nervous about a potential conflict, I went for it.

I was hoping to mount the Tyrolia Attack 13 demo's on it, which I've seen on closeout. I downloaded a paper template and held it up to the ski, and it seemed fine, but it's not exactly precise.

Can any folks with lots of binding experience chime in? Anyone recognize the hole pattern?

The Tyrolias have 95 mm brake, and this waist is 99, but in the FAQ of the site, they mentioned being able to mount the 95 mm brake on 104 mm waist.

If Tyrolias won't work, can I move to another brand with different hole pattern?

Thanks!