I continue to make progress on the shell. The last of the exterior shell construction is complete.

The next steps are to fabricate the 10 foot sections of 1/4 inch plywood for the triangular sides that will fold up when the roof is lifted which means more scarf joints. I have built a jig that allows me to quickly make the joint with a router. As it is only 1/4 inch, the joints are not as big as the ones for the 3/4 inch plywood.

Color has nearly been settled on. I thought I'd go with black on the area below the roof, with white on the rooftop. Pricing two colors of paint, I'm using Petit EZ-poxy one-part topside paint (a marine product), and to get the quantities I need would need to hope that the quarts I'd buy provide necessary coverage or get a gallon of single color. As it is easier to heat up the inside, when needed, versus cool it down, I've decided on white. Any suggestions for an alternative color for thermal and aesthetic reasons would be welcomed.

Truck photo for color reference.

I had thought I'd paint the interior white for brightness and easy of visibility, but have decided given the light color of the wood, that I'll just urethane it. It will reveal all the warts as well as construction notes I wrote on the pieces to keep the straight, but if I grow tired of that, I can always paint it, too.

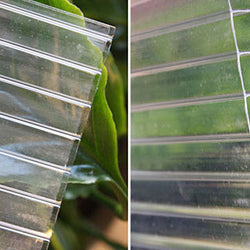

I'm going to glass the roof and its 3 inches of 'frame' for the sake of durability and additional stiffness, but I'm very happy with how strong the roof is as is. I had a suggestion from a woodworking friend not to rely on the arches solely for roof shape and added a couple of cross pieces that will prevent the roof frame from spreading under load. That proved to be a wise suggestion; I'm glad I implemented it.

The arches result in 3/4 of 'arch' once bonded with the roof while the two 1-inch cross pieces only impose slightly in the space below the roof. FYI, this is the roof raised from the front, not the back, as it will be completed.